Industrial scalability

From day one, Limenet has focused on the use of methods that allow the industrial scalability of the technology to gigatons.

Limenet plants are designed to be modular and consist of equipment already available on the market (e.g. calciners, CO₂ contactors, decanters, large pumps, pipes, etc.). Therefore, we can expect to have a replicability of large-scale plants at affordable costs thanks to the high degree of industrialization of each individual component. The Limenet team is structured to prepare every single site, which of course will require a specific project.

How to achieve scalability

The Limenet standard plant includes four main elements-requirements:

- Calcium carbonate

- Sea water

- Renewable electricity

- Port

- Biomass

Calcium carbonate represents about 7% of the earth’s crust, making it one of the most abundant minerals on Earth.

Similarly, seawater is simply accessible by installing plants on coastal areas. According to Caserini et al. the potential resource of limestone in the area within 10 km from the coast, in uncovered or covered by shrubs is relevant, about 4,000 Gton and rises to 15,000 Gton within 50 km from the coast.

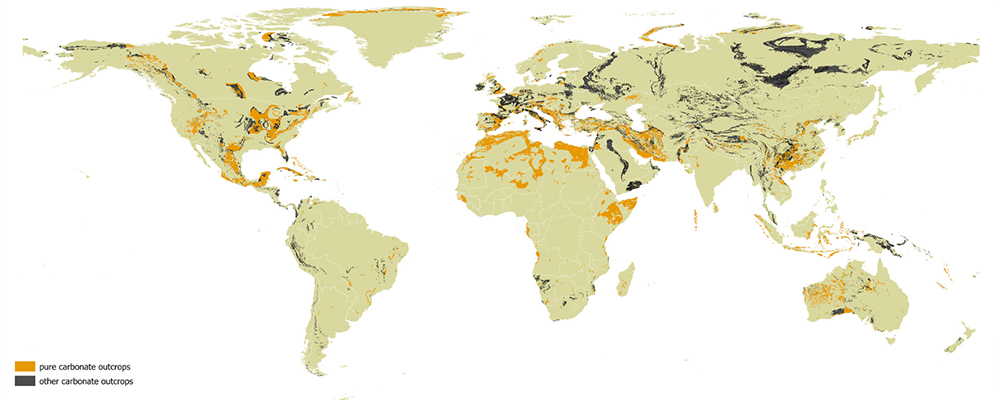

These quantities allow to capture and store several times the amount of CO₂ needed to solve the climate problem using Limenet technology. Limestone extracted from large quarries, far from a Limenet plant, can be easily and economically transported by ship from any quarry to the Limenet plant. According to the geographical distribution of pure carbonate deposits, it is possible to see that most of them are concentrated in desert and inhabited areas, such as North Africa, Somalia, Southern Australia allowing less negative impact on their extraction on the Gton scale.

The extraction of limestone on a large scale necessary to address the problem of climate change is a matter of concern by several authors such as Sengupta¹ that can generate “adverse environmental impacts of mining include ground vibration from blasting, noise pollution, poor soil and air quality as a result of dust, low quality and quantity of surface water and groundwater, air and water pollution, both on and off the mine site, increase in truck traffic transporting mineral, sedimentation and erosion, and land subsidence”. According to Sengupta ” all these factors have direct impacts on wildlife habitat, forestland and recreational land, human habitat, physical, mental, and social wellness, food security, and cultural and aesthetic resources”².

The development of a large mining industry for Limenet technology should be done according to environmental justice.

For example, it can be promoted in inhabited coastal areas, with the best mining technologies available and with the creation of well-organized living areas for workers and their families to avoid “demographic changes involving a structural and functional transformation of the social environment, including changes in gender balance, an increase in the non-resident labor force, pressures on infrastructure, land appropriation by local communities, housing and services, social inequality, poor child development and educational outcomes, pressures on families and relationships, drug and alcohol abuse, decline in subsistence and community lifestyles and impacts on indigenous communities”.

Due to the modularity of the industrial plants, Limenet can be implemented without further geographical constraints on inhabited coastal areas with low LCOE (level energy cost).

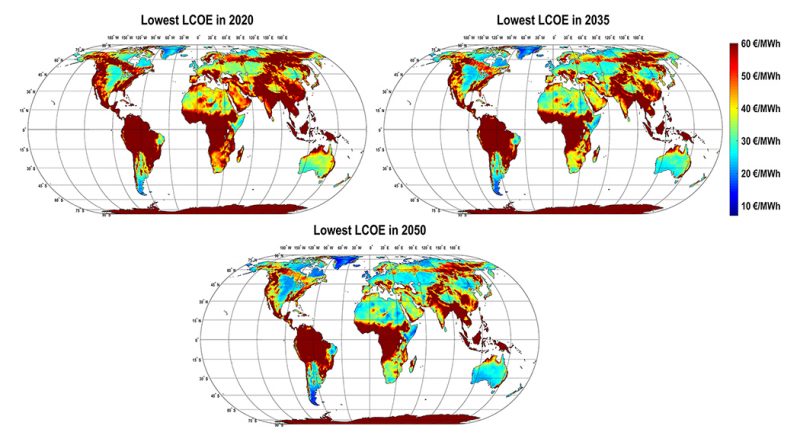

To achieve the long-term target of around $100/tons of CO₂, we have estimated a target energy price of between $15 and $25/MWh. In this regard, according to the study conducted by Satymov et al., the technology that guarantees the lowest LCOE is on-shore wind.

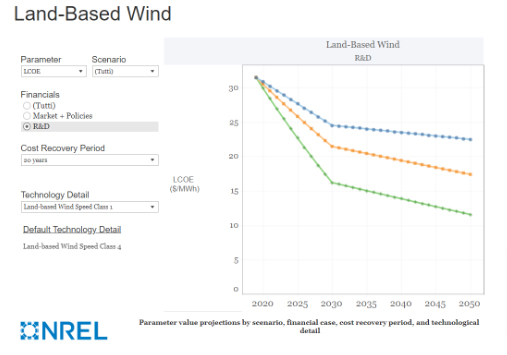

To reach the target energy price, you need a Class 1 wind with an average speed of 10 m/s. This analysis was supported by the National Renewable Energy Labs (NREL) providing an open source tool that can calculate the LCOE based on different technical and financial parameters. Considering 20 years of duration, wind class 1 and a sensitivity on the financial scenario, we have developed the following forecast:

Parameter value projections by scenario, financial case, cost recovery period, and technological detail

As shown, the sensitivity of the scenario shows the range between which LCOE is expected, in line with our energy target price for long-term vision.

A further analysis of the geographical sites can be made using the Global Wind Atlas dashboard that clearly shows those areas compatible with the wind class 1.

An example is Patagonia, in Argentina, where the average speed exceeds even the average of 10 m/s defined by class 1, reaching 14 m/s. Other examples are in Iceland, Greenland, Falkland, southern Chile and the Aleutian Islands (Alaska).

All the territories mentioned above are largely inhabited by thousands of kilometers of coastal, cold and, in some cases, undersea waters (e.g. Aleutian Islands) with large territories available to install onshore wind turbines.

Several multi-million-dollar installations could be installed in specific areas with already low-cost renewable electricity available and not densely populated (for example Northern Norway)but it is difficult to find enough seats and low additional electricity LCOE to grow up to the Gton scale: Norway can enjoy the existing hydroelectric facility with cheap electricity, but it is not the best place for low LCOE wind power.

Other territories, potentially suitable for the construction of Limenet plants (for example Scotland and Ireland) could encounter problems because they are populated areas where the installation of large wind projects could be difficult and in competition with local renewable energy generation needs.

Hot desert places with a mix of sun and wind could be suitable places (for example Somalia, Morocco, Egypt, Libya, Oman, Western Sahara, Mauritania etc.) but should be carefully evaluated for both LCOE and high water temperature which imply additional pumping requirements for Limenet plants to avoid abiotic precipitation during the process and further water losses in the air contactor due to evaporation involving larger desalination RO plants.

The modularity of the Limenet allows a limited construction period (from 1 to 2 years for 1 mton/year) and excellent planning of projects. The size of the project that will optimize the economic and technical parameters seems to be 1 mton/ a of CO₂ captured and stored. Once the technology is fully accepted, several parallel plants could be programmed simultaneously in rotation, financial investment being the only constraint: this feature of Limenet technology is unique compared to the geological CCS that, by definition, it is customized, large-scale with very long and unpredictable times to be operational.

Limenet technology will mainly rely on the use of waste biomass as a primary source of energy, as this provides both the heat needed for calcination and the carbon dioxide to be captured and stored. This approach will prevent the release of carbon dioxide into the atmosphere during the waste disposal process. By 2030, it is predicted³ that around 1100 million tonnes of biomass will be available in Europe from various sources, including cereal straw, agricultural pruning, secondary agricultural residues, stem wood, secondary forest residues, maize storage, manure, lignocellulosic crops and primary forest residues, in addition to biological waste. Considering that one tonne of biomass produces on average more than one tonne of CO₂, the use of these residues will allow a scalability of Limenet technology in the order of megatons.

Legal and regulatory compliance

The Limenet industrial plant is dumping alkalinity into the sea. The discharge into the sea of alkaline water at pH 8 is not considered harmful to the environment by European International Law 91/271/EEC (and should be similar in other countries outside Europe).

For the first Limenet plants it should be easy to obtain operating permits according to current environmental regulations, as Limenet did for its existing prototype plant with the Italian environmental agency. For the further spread of Limenet installations, with the release of huge quantities of alkaline water into the sea, the authorities will certainly analyse the environmental implications of this technology and promote regulations accordingly. The introduction into the sea of calcium bicarbonates produced by the Limenet process must be traced and regulated. Limenet has already obtained the permit obtainable through Single Environmental Authorization for the pilot plan of La Spezia and is in phase of approval for the plant TRL7 of Augusta following the application at the Unique Counters for the Productive Activities (SUAP).

Conclusions

In conclusion, there are no specific limitations for the implementation of technology on a different scale Gton/year, except for the requirement of affordable electricity, limestone, seawater and coastal areas available where to install Limenet plants. The carbon-free electricity source (i.e., renewable, nuclear or geothermal) must be used to increase the overall carbon efficiency of the process, so windy and sunny areas are preferred, particularly near large limestone deposits and on the coast. The world’s deposits of pure CaCO3 near coastal areas are many times larger than required for the large-scale OAE.

Windy places with available and inhabited coastlines such as, among others, Northern Norway, Aleutian Islands, Alaska, Canadian Newfoundland, Falkland Islands, Shetland Islands, Faroe Islands, Svalbard Islands, Greenland, Chilean Patagonia, Argentinian Patagonia, with cold and, in many cases, with aragonite sub saturation could be sufficient for the deployment of plants that generate a total of several gtons of CDR.

Warm and sunny places with available and inhabited coasts could also be considered, but the efficiency of the Limenet process will be affected by the increased saturation state of hot sea water aragonite which brings more pumping energy for better final dilution of the ionic waters discharged by the Limenet process and a higher LCOE potential.

The injection of bicarbonates into the sea, which play a beneficial role in the marine environment by reducing the acidification of the seas and oceans by alkalinization⁴,⁵,⁶, is classified by the Italian legislation as the release of “industrial waste water”. This categorization does not reflect the positive properties of bicarbonates in alkalinization and in the mitigation of marine acidification. Limenet aims to achieve long-term recognition of storage by bicarbonates as a separate method from industrial waste water. To achieve this, we consider it essential to be included in the Integrated National Energy and Climate Plan (PNIEC) as a technology that, in addition to removing CO₂ from the atmosphere, counteracts marine acidification.

Sources

¹ Sengupta, M. 2021. Environmental Impacts of Mining: Monitoring, Restoration, and Control

² A Research Strategy for Ocean-based Carbon Dioxide Removal and Sequestration (2022): DOI 10.17226/26278

³ https://www.concawe.eu/wp-content/uploads/Sustainable-Biomass-Availability-in-the-EU-Part-I-and-II-final-version.pdf

⁴ Gattuso, J.-P., et al. (2015) Contrasting futures for ocean and society from different anthropogenic CO₂ emissions scenarios

⁵ Doney, S. C., Fabry, V. J., Feely, R. A., and Kleypas, J. A. (2009) Ocean Acidification, Ann Rev Mar Sci, 1, 169–192

⁶ Suessle et al., 2023. Particle fluxes by subtropical pelagic communities under ocean alkalinity enhancement