Limenet has industrialised the geological carbon cycle by developing a technology that canto permanently store CO₂ through calcium bicarbonates in the oceans.

The raw materials used in this process are sea water, carbon dioxide and calcium carbonate.

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

|

|---|

|

|---|

|

|---|

|

|---|

Thanks to natural chemistry, Limenet is able to react CO₂ with calcium carbonate, producing calcium bicarbonate.

The acceleration of this natural process occurs thanks to the use of electrical and thermal energy in the system.

Based on the energy cost and the resulting carbon footprint, Limenet is testing several solutions that allow the hybrid operation of the plant with electricity or biomass.

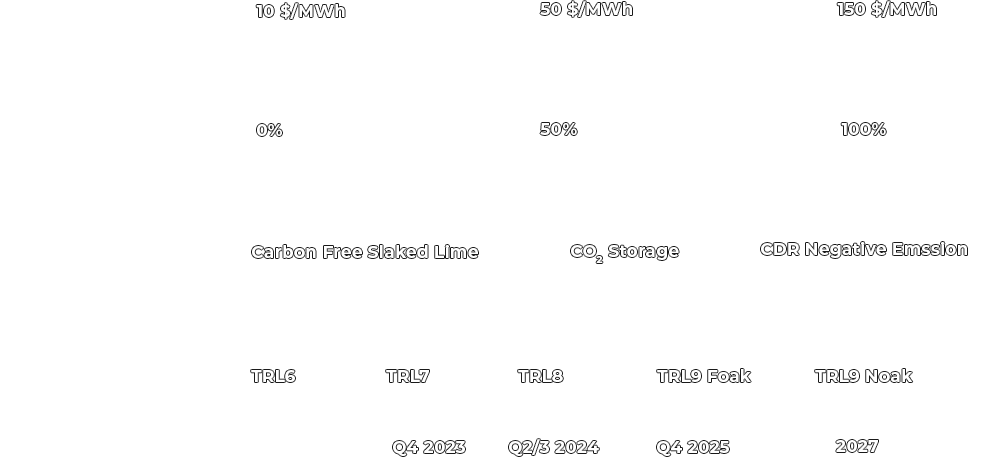

The three phases of Limenet technology

1. Crushing - Calcination – Hydration

The limestone raw material (CaCO₃) is crushed, calcined and then separated into CaO (quicklime) and CO₂, by thermal decomposition in an electrical furnace powered by renewable electricity.

The quicklime is then hydrated to obtain slaked lime (Ca(OH)₂)).

2. CO₂ abatement and production of calcium bicarbonate

Just over half of the slaked lime obtained is used to remove the carbon dioxide produced by calcination. The process takes place in the Limenet reactor, mixing CO₂ and Ca(OH)₂ in seawater: Ca(OH)₂ + 2CO₂ → Ca(HCO₃)₂.

The other half of the slaked lime (Carbon-free) is available for downstream carbon sequestration in phase 3.

3. Storage of CO₂

Half of the carbon free slaked lime is used to store CO₂ from external sources in the form of calcium bicarbonates. Calcium bicarbonate Ca(HCO₃)₂ product enriches seawater with its alkaline properties.

Limenet usage contexts

Options for the storage of CO₂

Limenet can be coupled to different sources of CO₂ emissions. Carbon dioxide, in fact, can be captured through different carbon capture systems and, subsequently, stored through our technology.

DAC (Direct Air Capture) + Limenet

This system involves coupling Limenet with a Direct Air Capture (DAC) system, provided by external partners, able to capture a pure flow of CO₂ from the atmosphere.

Hard to Abate Industry + Limenet

In the “hard to abate” industrial sectors where CO₂ is produced during the process (for example, metallurgical industry, shipbuilding, etc.), it is possible to couple a CO₂ capture system from flue gases to its subsequent storage via Limenet.

Point source of CO₂ + Limenet

In industrial systems that produce large quantities of carbon dioxide and have no capacity for reuse, Limenet can be used for the storage of CO₂ in seawater.